A retail operations director shares why radio-frequency identification transformed their business when traditional counting methods kept failing.

Marcus Reynolds has spent twenty-three years in retail operations management. He currently serves as Director of Operations for a mid-sized specialty retail chain with seventeen locations across the western United States. Three years ago, his company faced a persistent problem that was costing them money, damaging customer relationships, and creating operational headaches that no amount of staff training seemed to solve. Inventory accuracy hovered around 87 percent despite manual counts happening quarterly. Stockouts were common. Overstock tied up capital. The disconnect between what their system said they had and what actually sat on shelves was eroding profitability.

The solution came from technology Marcus had heard about for years but dismissed as too expensive and too complicated for their operation. Radio-frequency identification, commonly known as RFID, changed how his company tracks inventory, manages stock levels, and operates on a fundamental level. The implementation was not simple, but the results justified every dollar and every hour invested in the transition.

We spoke with Marcus about what drove the decision to adopt RFID, how the implementation process unfolded, and what the technology has meant for their bottom line and operational efficiency.

The problem was costing real money

Marcus does not soften the reality of where things stood before RFID implementation. His company was losing money in multiple ways that all traced back to inventory accuracy problems. They were marking down merchandise they thought was not selling, only to find cases of it sitting in the back room months later. They were disappointing customers by showing items as available online when stores were actually out of stock. They were ordering products they already had because no one could find them in time. They were paying staff to conduct manual counts that took hours, disrupted operations, and still produced unreliable data.

“We knew we had an inventory problem,” Marcus says. “What we did not fully understand until we started analyzing it seriously was how much that problem was costing us. When you factor in lost sales from stockouts, the carrying costs of excess inventory we did not know we had, the labor hours spent on manual counting, and the customer service issues from inaccurate availability information, we were looking at losses that ran into six figures annually. That was unsustainable for a company our size.”

Traditional inventory management relied on manual counting, barcode scanning, and periodic physical audits. The process was time-consuming and prone to human error. Staff had to handle every item, scan it, record quantities, and reconcile discrepancies. The counts disrupted normal operations because they required significant labor hours and often happened after hours or during closed periods. Even with careful execution, the accuracy rates remained unacceptable. The fundamental limitation was that barcode systems require line-of-sight scanning and individual item handling. That creates bottlenecks and introduces error at every step.

Why RFID made sense despite the cost

Marcus researched RFID technology for nearly eight months before recommending it to executive leadership. He knew the upfront investment would be substantial. Every item would need RFID tags. The company would need readers, antennas, and infrastructure at every location. They would need software integration with existing systems. Staff would require training. The total cost ran well into six figures.

What convinced him the investment made sense was the return on investment calculation. RFID would increase inventory accuracy to above 98 percent. The technology would enable real-time visibility into stock levels across all locations. It would reduce labor costs associated with manual counting by approximately 70 percent. It would minimize stockouts and overstock situations. It would improve the customer experience by providing accurate online inventory information. It would reduce shrinkage by making it easier to identify discrepancies quickly.

Marcus presented leadership with detailed projections showing the technology would pay for itself within eighteen months through a combination of increased sales, reduced carrying costs, labor savings, and shrinkage reduction. The data convinced them to move forward. The decision was not about adopting flashy new technology. It was about solving a chronic problem that was measurably damaging the business.

Implementation required careful planning

Rolling out RFID across seventeen locations was not something Marcus and his team took lightly. They started with a pilot program in two stores, working with a vendor who specialized in retail inventory management solutions. The pilot phase lasted three months and served multiple purposes. It helped them understand the technical requirements, identify potential problems, refine processes, and train staff on the new system before committing to a full rollout.

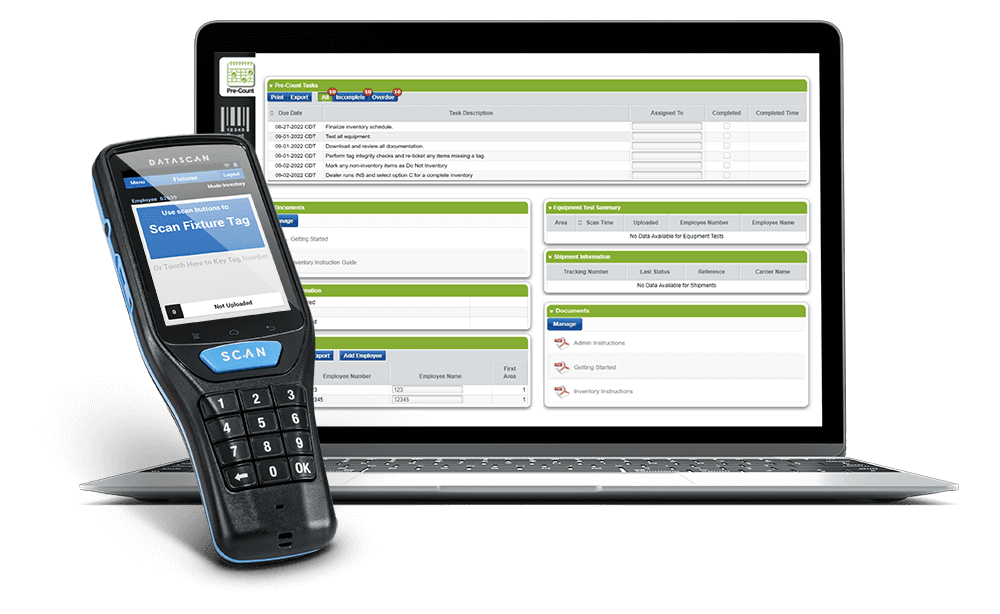

The technical implementation involved several components working together. RFID tags had to be attached to every piece of merchandise, either by manufacturers, distributors, or store staff depending on the product category. Fixed readers were installed at key points including receiving areas, storage rooms, and exits. Handheld readers allowed staff to conduct quick counts and locate specific items. The RFID system integrated with their existing point-of-sale and inventory management software to provide real-time data updates.

Staff training was critical to success. Employees needed to understand how RFID worked, why it mattered, and how it would change their daily responsibilities. Marcus and his operations team developed training materials, conducted workshops at each location, and designated RFID champions at every store who could troubleshoot issues and reinforce best practices. The transition disrupted normal operations temporarily, but careful planning and phased rollout minimized the impact on customers and sales.

The most challenging aspect was not the technology itself but changing established workflows and convincing staff who had done things the same way for years that the new system was worth the learning curve. Marcus addressed resistance by being transparent about the problems the company faced, explaining how RFID would make their jobs easier once implemented, and demonstrating results from the pilot stores where inventory accuracy had improved dramatically and staff were spending less time on manual counting.

The results exceeded projections

Within six months of full implementation, inventory accuracy across all locations reached 99.2 percent. Stockouts decreased by 68 percent. Overstock situations declined by 54 percent. The time required to conduct physical inventory counts dropped from an average of twelve hours per location to under two hours. Labor costs associated with inventory management fell by approximately $180,000 annually across the chain.

Customer satisfaction improved measurably. Online orders were fulfilled more reliably because the system accurately reflected what was actually available. Customers arriving at stores based on online inventory checks found the items they came for. The reduction in frustration and wasted trips translated into better reviews, increased loyalty, and higher conversion rates. Shrinkage also dropped significantly because RFID made it easier to identify discrepancies in real time rather than discovering theft or loss months later during physical counts. The technology also improved visibility into supply chain processes, helping the company identify inefficiencies in receiving, stocking, and merchandise handling that had previously gone unnoticed.

Marcus emphasizes that these results required ongoing attention and optimization. RFID is not a set-it-and-forget-it solution. The system requires regular maintenance, tag replacement, software updates, and process refinement. The company invested in dedicated personnel to manage the RFID infrastructure and ensure it continued delivering accurate data. That ongoing investment has proven worthwhile because the operational improvements and cost savings compound over time.

What other business leaders should consider

Marcus is direct about his recommendations for business leaders considering RFID adoption. The technology is not appropriate for every situation, but for businesses facing persistent inventory accuracy problems, it often represents the most effective solution available. The key is approaching implementation strategically rather than treating it as a simple technology upgrade.

Start with a clear understanding of your current inventory costs and challenges. Quantify the losses from stockouts, overstock, shrinkage, and labor inefficiency. Calculate the potential return on investment based on realistic improvement projections. Present leadership with data-driven business cases rather than technology enthusiasm. Executive buy-in requires demonstrating financial impact, not technological capability.

Choose implementation partners carefully. Look for vendors with proven experience in your industry who can provide end-to-end inventory solutions including hardware, software, integration, training, and ongoing support. Avoid the temptation to cobble together systems from multiple vendors unless you have significant internal technical expertise. Integration challenges can derail implementations and erode the benefits RFID should deliver.

Plan for a phased rollout that allows you to learn and adjust before committing fully. Pilot programs identify problems when they are still manageable rather than discovering them after you have invested millions across your entire operation. Use pilot results to refine processes, improve training, and build internal support for broader implementation.

Invest seriously in change management and staff training. Technology only delivers results when people use it correctly and consistently. Employees need to understand why the change matters, how it benefits them personally, and what they need to do differently. Resistance to change will undermine even the best technology if not addressed proactively.

The competitive advantage compounds over time

Three years into RFID implementation, Marcus sees the decision as one of the most impactful operational improvements his company has made during his tenure. The direct financial returns have exceeded initial projections. The operational efficiencies continue improving as staff become more proficient with the system and the company identifies additional applications for the technology.

The competitive advantage extends beyond immediate cost savings. Accurate inventory data enables better buying decisions, more effective merchandising, and faster response to changing demand patterns. Real-time visibility into stock levels across all locations allows the company to move inventory between stores to fulfill customer demand rather than marking products down or disappointing shoppers. The ability to provide customers with reliable inventory information online has become a significant differentiator in a market where competitors still struggle with accuracy.

Marcus believes RFID adoption will eventually become necessary for survival in retail rather than just a competitive advantage. Customer expectations around inventory accuracy, fulfillment speed, and omnichannel shopping continue rising. Meeting those expectations without real-time inventory visibility becomes increasingly difficult. Companies that wait too long to adopt these technologies will find themselves at a disadvantage that becomes harder to overcome as competitors pull ahead.

The lesson Marcus draws from his experience is straightforward. Chronic operational problems rarely resolve themselves through incremental improvements. Sometimes solving them requires significant investment in new approaches, technologies, or systems that fundamentally change how work gets done. The key is making those investments strategically, based on clear analysis of costs and benefits, implemented thoughtfully with appropriate planning and change management. When done right, the results justify the effort many times over.